About the Author

Everest Fernandez @everestF is a passionate grower, writer, and online educator living in southern France. He grows indoors and outdoors, primarily to supply his home kitchen – with a focus on exotic, hard-to-find herbs and vegetables. A seasoned prepper and liberty lover, Everest believes that local, sustainable food production is the foundation of building resilient communities.

Introduction…

I’ve been keeping up with the latest and greatest LED grow lights for a little over five years now. I started out somewhat sceptically and tentatively, incorporating a few LED bar fixtures alongside my existing double-ended HPS (DE-HPS) and ceramic metal halide (CMH) grow lights in a bid to extend footprints and improve spectral quality. After some promising initial results, I moved to running LED-only rooms, but it was this transition that turned out to be the most challenging.

Suffice to say, if you’re growing light-loving, heavy-fruiting, herbaceous annuals and you’re thinking of changing from HPS to LED, or from CMH to LED, there are some important tips and heuristics to be aware of. I’ve spoken to many growers who have dismissed LEDs after their initial yields fell short of expectations, both in terms of quantity and quality. I understand only too well that, after months of hard work, these disappointments can be very hard to bear and it’s easier and less painful for some growers to lay all the blame at their new lights (or nutrients, or seeds) rather than to reconsider their growing practices.

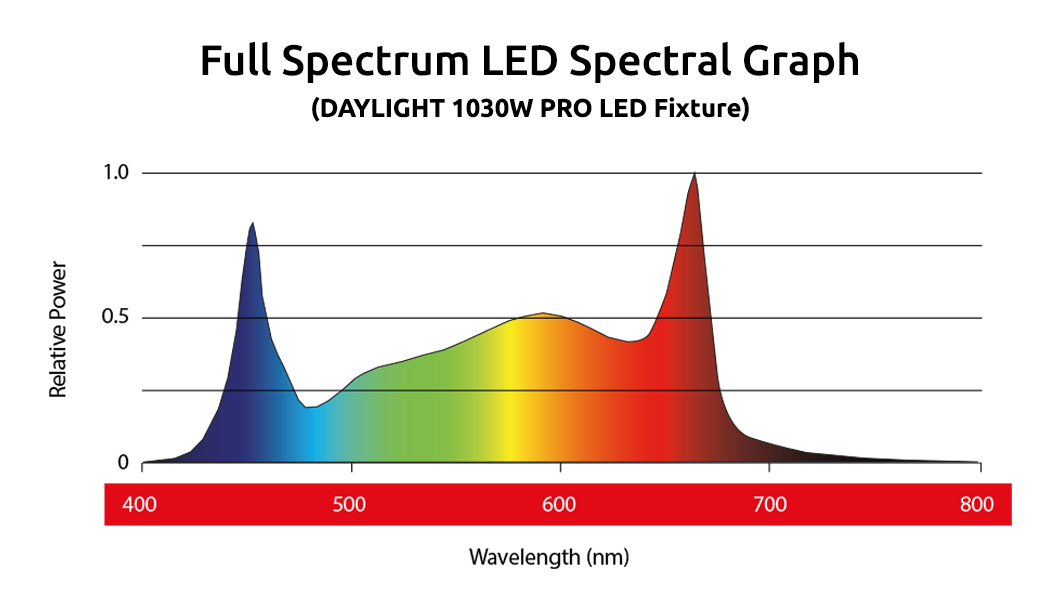

1. Don’t be swayed by efficiency claims! Always check the spectrum and output (PPF)

PPF stands for Photosynthetic Photon Flux and refers to the amount of plant-usable (PAR) light produced by a lighting fixture in one second. As such, PPF is measured in μmol/second.

What does “μmol/s and PPF” mean?

µmol/s stands for “micromoles per second “ and is the amount of light (photons or particles of light) that drives photosynthesis. The higher the PPF the greater the output of plant usable light, measured in μmol/s. But the story doesn’t end there…

A lot of growers are sold on LEDs because they’re more efficient than legacy lighting technologies. In other words, indoor cultivators want to upgrade to LEDs because they believe they will use less electricity—the rule of thumb being, “If it’s more efficient, it’s more cutting-edge, therefore it’s better.” While an energy-efficient grow room is a noble goal, you really shouldn’t allow yourself to be swayed to buy one fixture over another because one light boasts 2.85 μmol/J on its packaging while another only claims 2.6 μmol/J.

What does “μmol/J and efficiency” mean?

μmol/J stands for “micromoles per joule” and is a measure of the efficiency of a light source. Put simply: how much light does a fixture produce for a given amount of electrical energy. The quantity of light is measured in micromoles because the sheer number of photons is so huge! Energy is measured in joules: one joule equals a watt of power during one second.

Example: A lighting fixture produces 1782 μmol/s using 660W of power. The fixture’s efficiency is 1782/660 = 2.7 μmol/J.

Sure—it’s tempting, as a consumer, to distill all the complexities of LED lighting into a single number—and lighting marketing departments know this! The reality of actual performance is a lot more nuanced, however. Let me put this another way: while fixture efficiency should certainly play a part in any purchasing decision, if an LED grow light manufacturer is crowing on and on about efficiency and little else, you should take those figures with a healthy pinch of salt and definitely not allow yourself to be distracted from the truly important metrics: spectrum and output!

Growing indoors, where grow lights are the sole light source, should ideally take place under full-spectrum light. Admittedly, your HPS or DE-HPS is far from full spectrum—as evinced by its characteristic yellow/orange glow. (That’s why quality-focused growers often mix HPS with MH or CMH.) As indoor growers, we always do well to remember that plants have evolved to exploit full-spectrum sunlight so it’s white, not yellow or red, light that’s our gold standard.

Monochromatic LEDs emit light within a relatively narrow band range. To create a full spectrum output, it’s necessary to add a phosphor coating—but this additional phosphor reduces overall output and therefore lowers efficiency. Full spectrum LEDs currently have an efficacy of around 2.5 to 2.7 μmol/J. Monochromatic red LEDs are up around 4.0 μmol/J.

So—if all you considered was the efficiency—you’d end up buying a red-heavy greenhouse style LED (after all, they’re rated at 3.5 μmol/J and higher!) but this would suck in an indoor setting. (Too much red in the absence of background solar radiation will cause bleaching of plant tops leading to necrosis and mould.)

Much, much more important is the total output (PPF) and the spectral quality. PPF gives you the total number of photons produced by the fixture during one second and checking the spectral quality for a nice, broad spectral distribution stops you falling for an under-powered LED with an overly red-heavy spectrum.

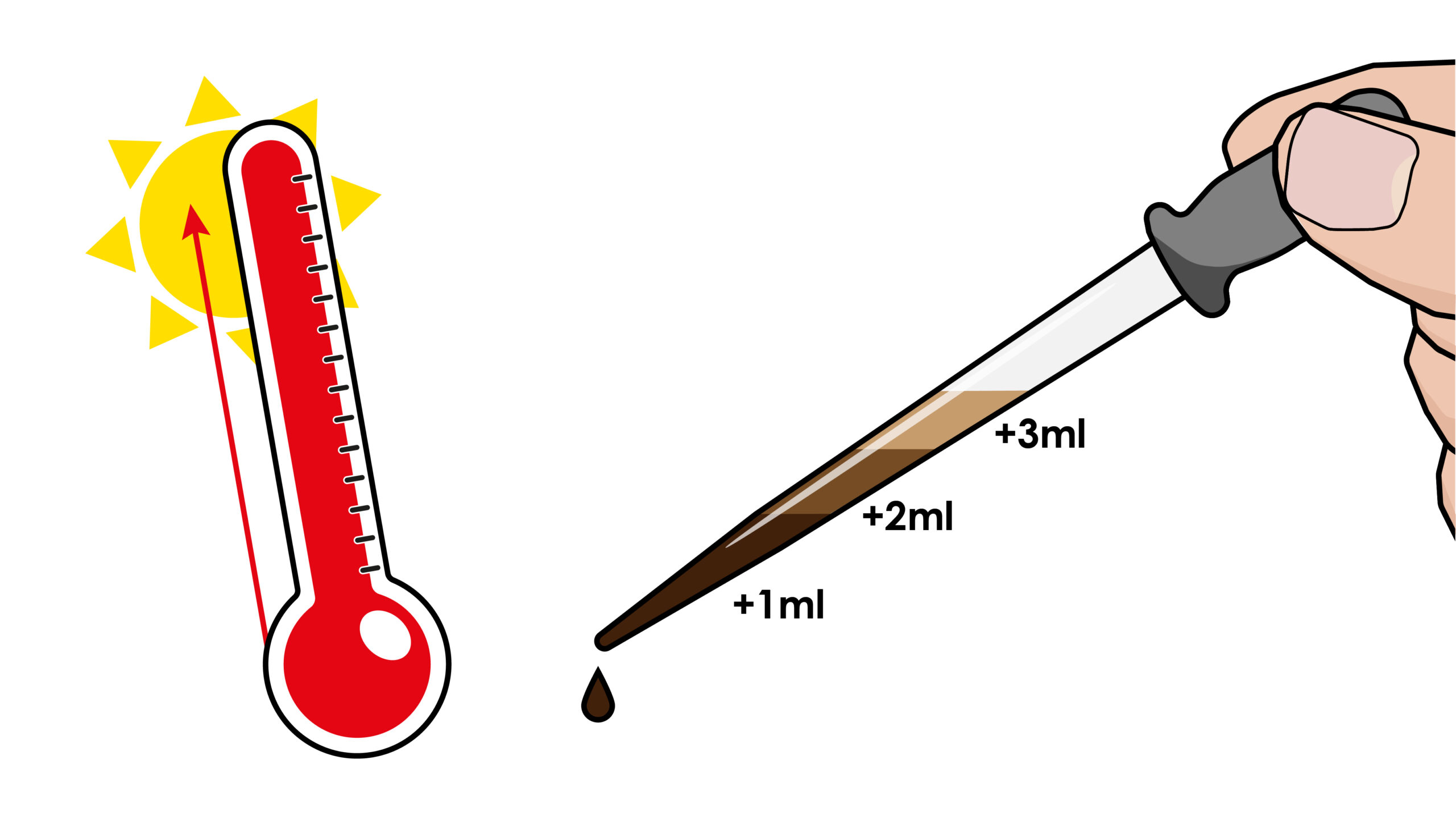

2. Higher nutrient strength or higher air temperature?

LED grow lights produce plenty of photosynthetically active radiation (PAR) but typically fall short on infrared. While radiant heat is often touted as the “bad guy” by some LED manufacturers, the truth is to be found somewhere in the middle. After all, half of incident solar radiation is made up of infrared. Plants, especially species native to cooler, higher altitudes, have evolved to rely on infrared to warm their tissues and kickstart metabolic processes. Infrared helps to drive transpiration which directly affects the uptake of key essential elements such as calcium. Some LED growers run their rooms with air temperatures a few degrees warmer to counter this lack of infrared radiation. Others increase the concentration of their feed solution—sometimes two- or three-times normal levels—using base nutrients that are low in nitrates.

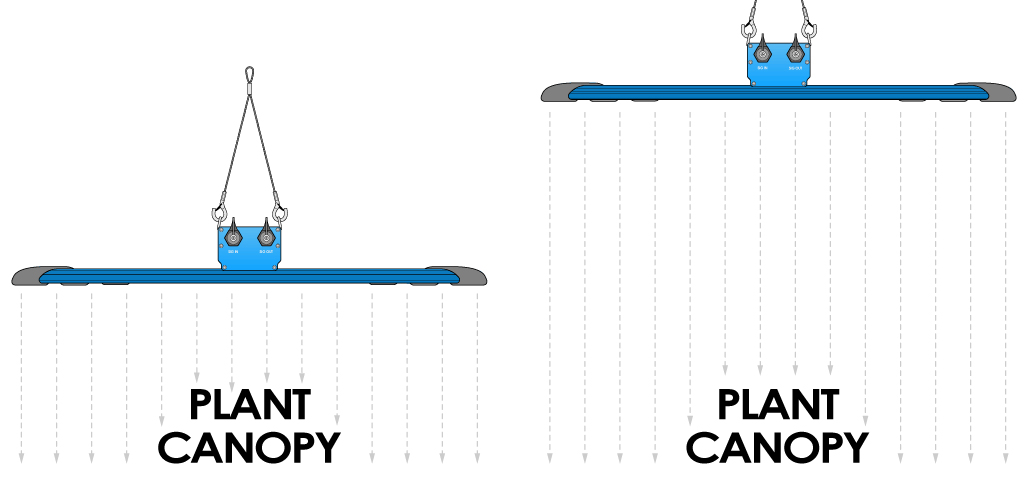

3. Check the recommended hanging distance

Don’t assume that all LEDs are built for proximity placement. While some multi-array fixtures based on medium power diodes can be placed 30 – 45 cm (12 – 18 inches) from the canopy, others require at least 90 cm (36 inches).

4. More dehumidification

If you’re running air conditioners or extraction fans connected to a thermostatic fan speed controller, you may find your grow room environment becomes more humid, especially during the second half of the lifecycle when plants are larger and transpiring more / creating humidity. LED grow rooms don’t tend to get so hot so your air conditioner and/or fans won’t need to work as much to maintain a given air temperature. As such, you may well need to invest in a dehumidifier to directly counteract high humidity levels. This is especially true of sealed rooms with elevated carbon dioxide levels.

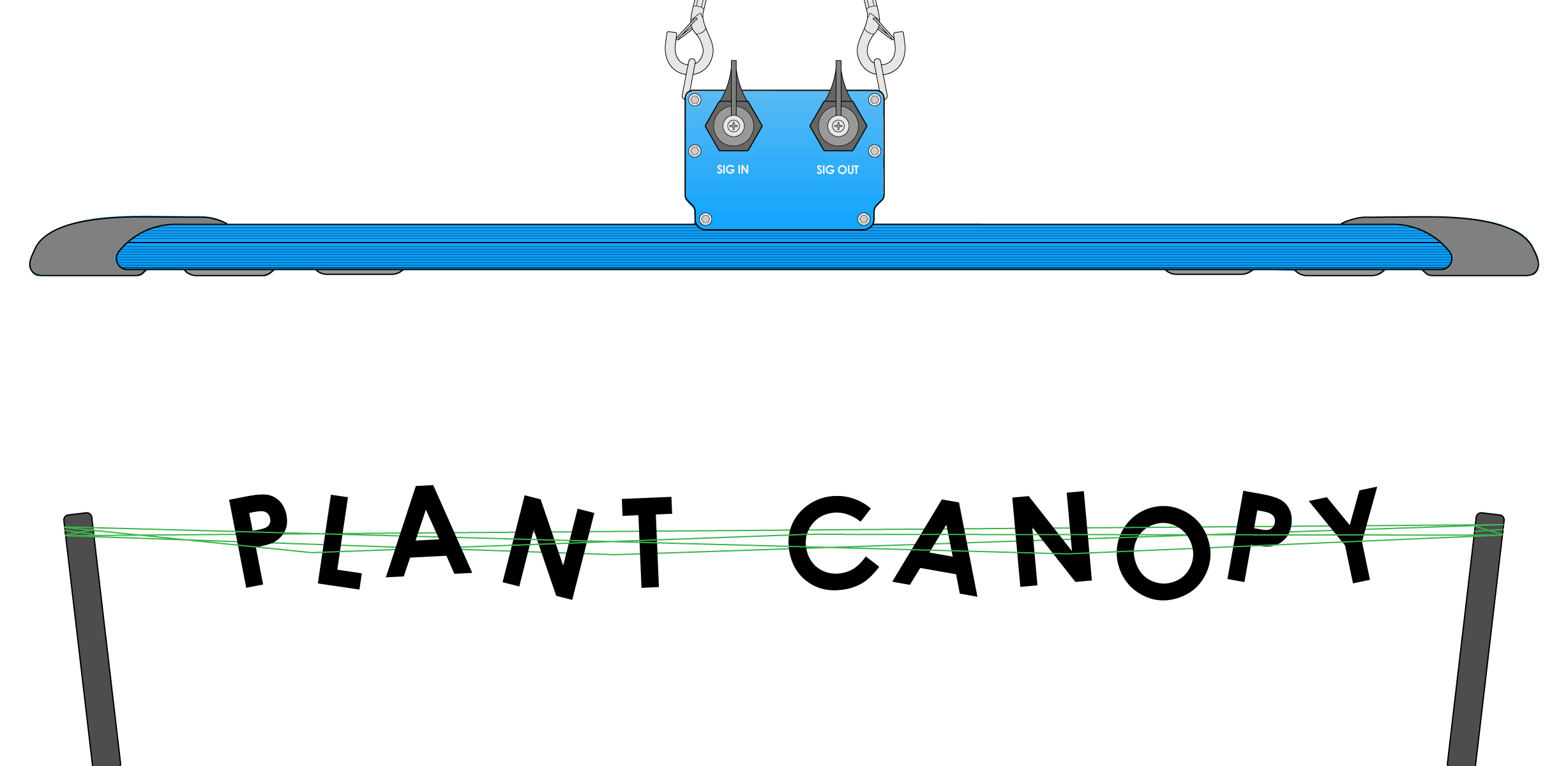

5. Grow squatter, bushier plants and spread them out with soft mesh netting

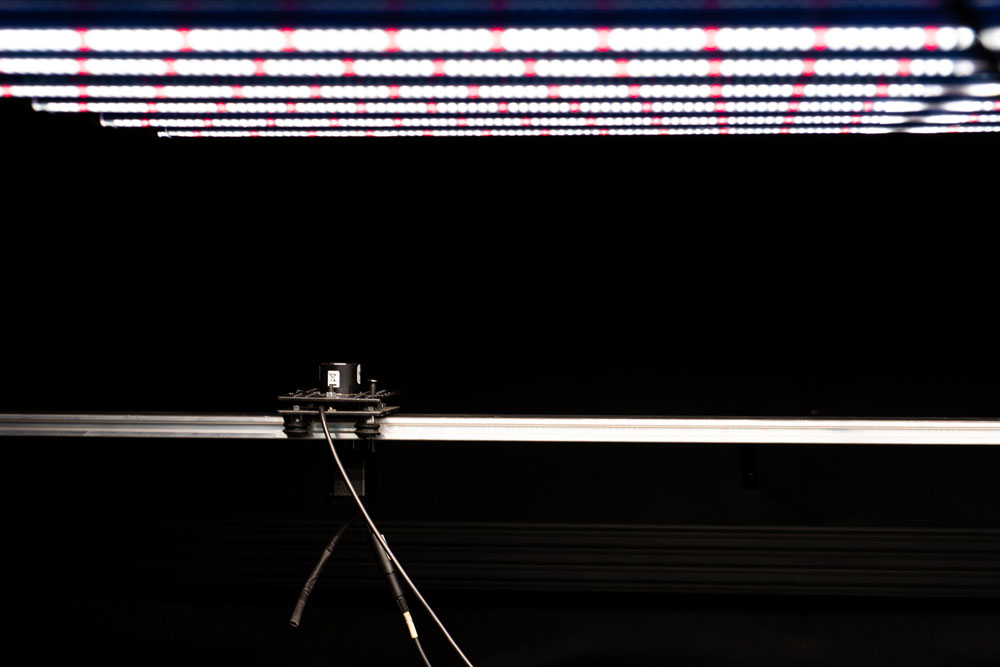

“Don’t grow Christmas trees,” a friendly man in a grow shop advised me many years ago, “Aim for a candelabra.” Great advice, no matter what kind of grow light you’re using—but it’s particularly pertinent for LEDs, despite this advice being dispensed decades before. In the vegetative cycle, plants grown under LEDs tend to stay squatter and more compact. Use soft mesh netting to train growth tips out to form a wide canopy. Your aim is to have as many flower/fruit sites at the same height—this really suits the form factor of multi-array LEDs with 6 to 8 bars spread out over a 1.2m x 1.2m area.

6. Matching the PPFD measured under your HPS / MH / CMH with LED probably won’t cut it

Too many indoor growers worship PPFD as the be all, end all measurement of light intensity for plants—even mistaking it as an indicator of the levels of actual photosynthesis taking place. Now, don’t get me wrong. A handheld PAR meter comes in handy when you need a quick snapshot of light intensity at a given position, but it doesn’t even get close to telling the whole story from a plant’s perspective. Let me explain…

PAR meter sensors are silicon photodiodes (like a “reverse LED” they convert light into electricity) housed within a translucent acrylic cap. The purpose of the cap is to diffuse and homogenize all incoming light. The amount of electricity generated is then “cosine corrected” according to the law of Lambertian reflectance and the resulting value is shown on the PAR meter screen as the PPFD in µmol s-1 m-2 (micromole per second per metre squared). However, the acrylic cap obfuscates the light source’s key characteristic—the photons’ directions of travel, relative to each other. Why is this important? Well, when all photons are traveling in the same direction, you have a laser. At the other end of the scale, you have diffused, scattered “cloud-cover” light. Light-loving species have evolved to exploit direct sunlight—where photons are pretty much traveling parallel to each other. Also, while plant leaves orientate themselves to capture as much light as possible (phototropism), PAR meter sensors are always held so they are level with the ground, perfectly horizontal. This measurement methodology favours “top-down” multi-array LED light sources and arguably produces higher PPFD values than more angular HID light that all emanates from the same arc tube.

What does this mean in practical terms? Attempting to match the measured PPFD from an HPS or CMH with an LED is a wrongheaded approach. HPS and CMH send out a lot of angular light to the sides—and this is useful for canopy penetration, whereas LEDs tend to be top down. Either grow higher numbers of smaller, shorter plants or, if bigger plants are your thing, consider side lighting.

7. Chances are you’ll need heaters in winter

HPS growers love winter! The cooler ambient temperatures offset the heat generated from the HPS making it much easier to dial in your grow room’s air temperatures. While heaters have long been used during the lights out period to keep temperature differentials to a minimum, you may find that you need to keep the heaters plugged in during the day cycle too!

8. More Plants, Less Veg, Harder Pruning

Some might say that I’ve saved the most important advice ‘til the end—perhaps to reward you valiant souls who stuck the course! If you’re growing under multi-array LEDs, then most of the light is raining in directly from above. The best way to exploit this is to grow a larger number of smaller plants—ideally homogenous cuttings taken from the same donor plants, subjected to some brutal sub-canopy stripping. Top the apical dominant growth tips of rooted cuttings as soon as possible. Prune off any lower branches and remove sub-canopy foliage to create a “sea” of growth tips basking in peak incident light intensity. Don’t expect multi-array LEDs to excel with large plants unless you’re willing and able to invest in high wattage LEDs or some serious supplemental side-lighting.